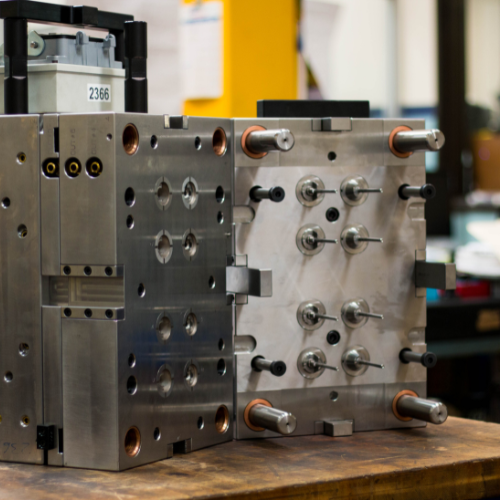

Mold making

Precision Molds, Perfect Parts.

We offer high-quality mold-making services through our trusted global partners, ensuring precision, durability, and cost efficiency. From prototype to production tooling, we deliver expertly crafted molds tailored to your exact specifications.

Custom Mold Design & Engineering

Expert DFM (Design for Manufacturability) to optimize part geometry for molding Mold flow analysis to predict and resolve potential defects Material selection guidance for durability and performance

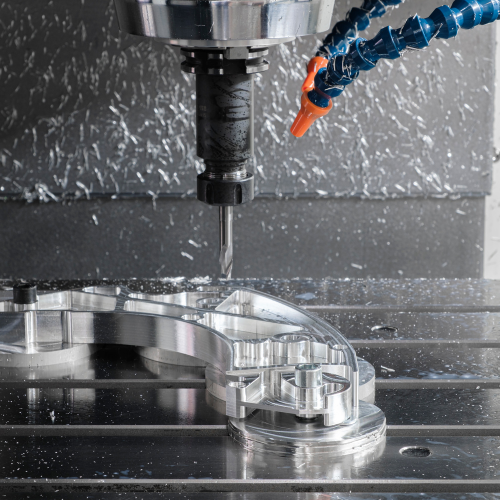

High-Precision Mold Manufacturing

CNC machining, EDM, and other advanced tooling methods Tight-tolerance mold production for medical, automotive, and consumer products Multi-cavity, high-volume, and prototype tooling solutions

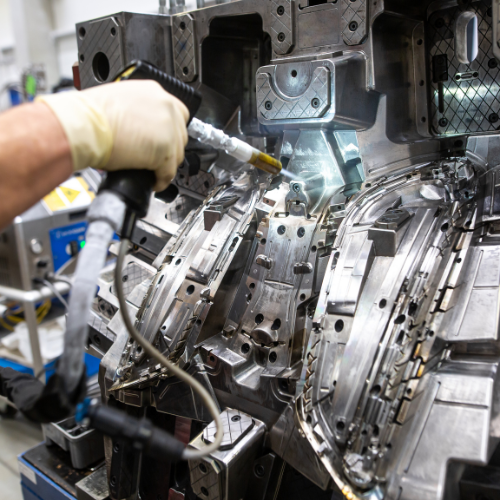

Mold Testing & Validation

In-house or partnered mold trials to ensure part quality Process validation support (IQ/OQ/PQ) for regulated industries Fine-tuning for cycle time optimization and longevity

Mold Maintenance & Support

Preventative maintenance programs to extend mold life Refurbishment, repairs, and modifications for existing molds Global support for on-site troubleshooting and process optimization

Why choose our mold making service

Choose our mold-making service for precision-engineered, high-quality molds tailored to your needs. We offer expert design, fast turnaround, and cost-effective solutions to ensure optimal performance and durability.

- Precision-engineered molds for high-quality parts.

- Fast turnaround with expert craftsmanship.

- Cost-effective solutions tailored to your needs.

What You Get

Get high-precision molds with expert DFM, robust validation, and optimized cycle times. We ensure superior quality, tight tolerances, and efficient production for your plastic parts. Reliable, cost-effective, and built to last.

- Expert Molding advice for Optimize design.

- Navigate supplier challenges, tooling, and process validation.

- Reduce cycle times, enhance quality, and ensure compliance.