Training

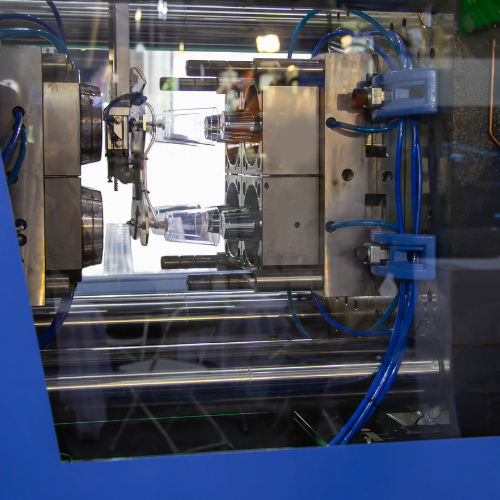

Expert Training for design &Manufacturing

Elevate your injection molding expertise with our comprehensive training. Covering Molding Process & SIM, Mold Testing & Validation, Mold Design, and Molding Quality Control, our courses provide the skills and knowledge to optimize efficiency, improve quality, and enhance overall production performance.

Moulding Process, SIM.

Master the Molding Process & Scientific Injection Molding (SIM) with our expert training. Learn process optimization, troubleshooting, and data-driven techniques to improve efficiency, quality, and consistency in injection molding production.

Mold Testing & Validation

Ensure precision and performance with our Mold Testing & Validation training. Learn industry-best practices for mold qualification, troubleshooting, and process validation to optimize production efficiency, reduce defects, and improve overall mold performance.

Mold design

Gain expert knowledge in Mold Design with our specialized training. Learn key principles, material selection, cooling strategies, and advanced design techniques to create efficient, high-performance molds for superior injection molding results.

Moulding quality control

Ensure superior product quality with our Molding Quality Control training. Learn key techniques in defect prevention, process monitoring, and quality assurance to maintain consistency, reduce waste, and meet industry standards in injection molding production.

1. Free Training call

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. Design for Injection Molding: Best Practices for Engineers

Who it’s for: Product designers, mechanical engineers, and DFM reviewers

What it covers:

Material behavior and selection for molded parts

Wall thickness optimization and uniformity

Ribs, bosses, snap fits, and living hinges: design rules

Gate, ejector, and parting line influence on part aesthetics

Draft angles and undercut elimination strategies

Common design flaws that lead to molding defects

DFM checklist and design review best practices

3. Fundamentals of Mold Design for Engineers

Who it’s for: Product developers, tooling engineers, and project managers

What it covers:

Core and cavity layout principles

Mold classifications (SPI types, hot vs. cold runners, etc.)

Gate types and placement strategy

Venting, cooling, and ejection system design basics

Mold steel selection and surface finish considerations

Design for maintenance and mold longevity

Interfacing between part design and toolmaker

4. Scientific Injection Molding (SIM) Essentials

Who it’s for: Process engineers, molding technicians, and production supervisors

What it covers:

The 5 key phases of the injection molding process

First-stage fill vs. second-stage pack and hold explained

Establishing a robust process window

Short shot, V/P switchover, and gate freeze analysis

In-mold pressure and cavity sensors overview

Real-world process troubleshooting (case studies)

Hands-on calculations and simulations (manual or software-aided)

5. Mold Testing & Validation: From T0 to Production Approval

Who it’s for: Engineers managing new tool launches or validation

What it covers:

T0–T2 testing overview and what to look for at each stage

Planning for IQ/OQ/PQ: what’s required and why it matters

DOE basics and building a robust validation matrix

Sampling strategies for new molds (shots, cycles, materials)

How to read and interpret CPK, PPK, and SPC charts

Preparing validation reports and client approval packages

Red flags during first-shot inspections and how to respond

6. Injection Molding Defect Analysis & Quality Control

Who it’s for: Quality engineers, process techs, and production leads

What it covers:

Identification of common defects: short shots, flash, warping, splay, sink, burn, etc.

Root cause analysis and machine/mold/material interplay

Process capability and control tools (Cp, Cpk, control charts)

Visual inspection standards (e.g., AQL, ANSI/ASQ Z1.4)

Real-world case reviews with images and sample parts

Creating effective inspection sheets and defect tracking logs

Preventive actions and continuous improvement strategies

Why Choose Our Molding Training?

Gain industry-leading expertise with our comprehensive, hands-on molding training designed for professionals at all levels. Learn from experts and stay ahead in the competitive world of injection molding.

- Expert-Led Training – Learn from experienced industry professionals.

- Practical & In-Depth Courses – Real-world applications and hands-on learning.

- Boost Efficiency & Quality – Optimize processes, reduce defects, and improve production.

What You Get

Gain practical skills and industry expertise with our molding training. Improve efficiency, quality, and innovation in injection molding.

- Hands-On Learning – Real-world applications and troubleshooting.

- Expert Guidance – Training from experienced professionals.

- Industry-Relevant Skills – Master processes, design, and quality control.